Chin-Yi Cheng

2017

BoxeSpiral Pavillion

Gaduate-level Optional Studio Project, Senior Year, 2011

In this project, I express my design intention through the correlation of structure, form and fabrication method. This pavilion has all the CNC-milling and assembling details, although not actually built.

Concept, Challenge and Solution

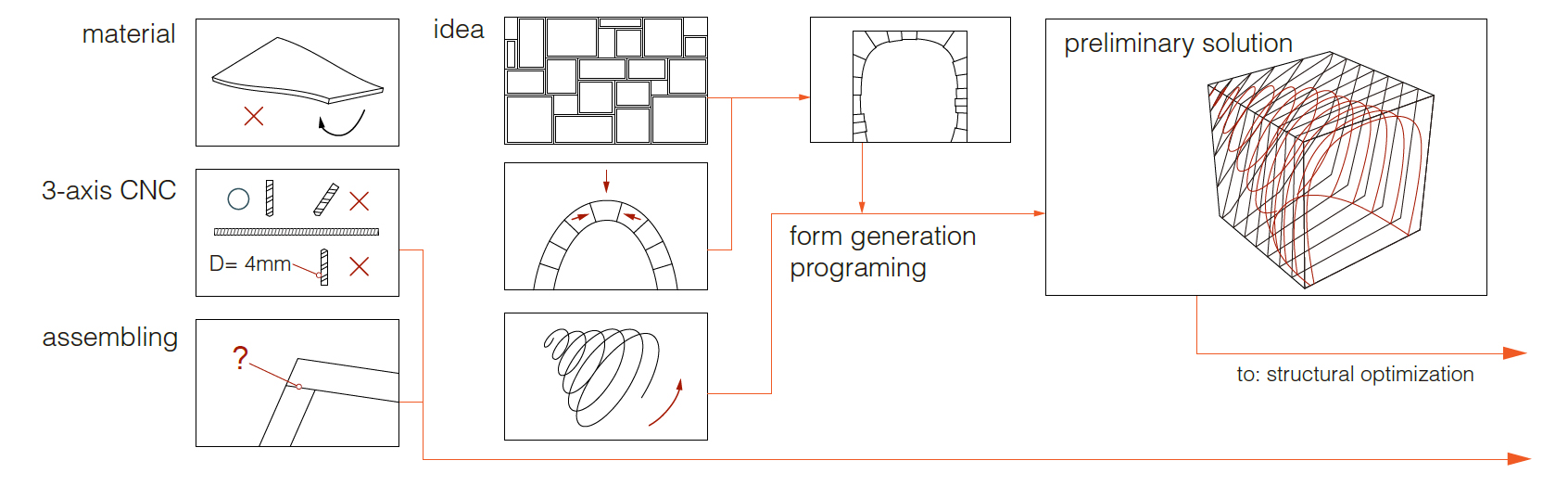

Stacking different size of boxes into a wall is not difficult, and stacking trapezoid boxes into arc shape is not difficult. But how about stacking different size of boxes in to a spiral shaped pavilion? The challenges would be:

1. The boxes are made by flat plywood plate, so we do not want to create curved plates.

2. We only have 3-axis CNC milling machine, so it cannot deal with double-sided milling.

3. We want to make a robust structure with the advantages of wedge joints.

Design and Optimization Process

During the geometry generating phase, the shape operation is carefully studied to make sure every plate is flat. Moreover, the structure optimization process is already embedded in this stage to arrange every box in a proper size and position.

In the phase of generating assembly and structural details, the system will analyze four basic joint types, and generate the optimal joints combination based on the strict constraint that the plate can be only machined one side.