Chin-Yi Cheng

2017

photo creadit: Rob Chron

bioLogic

bioLogic is growing living actuators and synthesizing responsive bio-skin in the era where bio is the new interface. We are Imagining a world where actuators and sensors can be grown rather than manufactured, being derived from nature as opposed to engineered in factories.

bioLogic seeks a harmonious perspective, where biological and engineering approaches flow in sync. These animate cells are harvested in a bio lab, assembled by a micron-resolution bio-printing system, and transformed into responsive fashion, a “Second Skin”. We can now observe the self-transforming biological skin activated by living bacteria. The synthetic bio-skin reacts to body heat and sweat, causing flaps around heat zones to open, enabling sweat to evaporate and cool down the body through an organic material flux. In collaboration with New Balance, bioLogic is bringing what once may have lived in the realm of fantasies into the world of sportswear.

Publication

Science Advances

Harnessing the hygroscopic and biofluorescent behaviors of genetically tractable microbial cells to design biohybrid wearables.

Wen Wang, Lining Yao, Chin-Yi Cheng, Teng Zhang, Hiroshi Atsumi, Luda Wang, Guanyun Wang, Oksana Anilionyte, Helene Steiner, Jifei Ou, Kang Zhou, Chris Wawrousek, Katherine Petrecca, Angela M. Belcher, Rohit Karnik, Xuanhe Zhao, Daniel I. C. Wang, and Hiroshi Ishii. 2017.

Science Advances 3, e1601984.

CHI 2016

xPrint: A Modularized Liquid Printer for Smart Materials Deposition.

Guanyun Wang, Lining Yao, Wen Wang, Jifei Ou, Chin-Yi Cheng, Hiroshi Ishii. 2016.

In Proceedings of the 2016 CHI Conference on Human Factors in Computing Systems (CHI ‘16). ACM, New York, NY, USA, 5743-5752.

CHI 2015 | Best Talk award | Honorable Mentions award

bioLogic: Natto Cells as Nanoactuators for Shape Changing Interfaces.

Lining Yao, Jifei Ou, Chin-Yi Cheng, Helene Steiner, Wen Wang, Guanyun Wang, and Hiroshi Ishii. 2015.

In Proceedings of the 33rd Annual ACM Conference on Human Factors in Computing Systems (CHI ‘15). ACM, New York, NY, USA, 1-10.

3D Printing and Additive Manufacturing Journal | Invited Paper | Cover Feature

bioPrint: A Liquid Deposition Printing System for Natural Actuators.

Lining Yao, Jifei Ou, Guanyun Wang, Chin-Yi Cheng, Wen Wang, Helene Steiner, and Hiroshi Ishii. 2015.

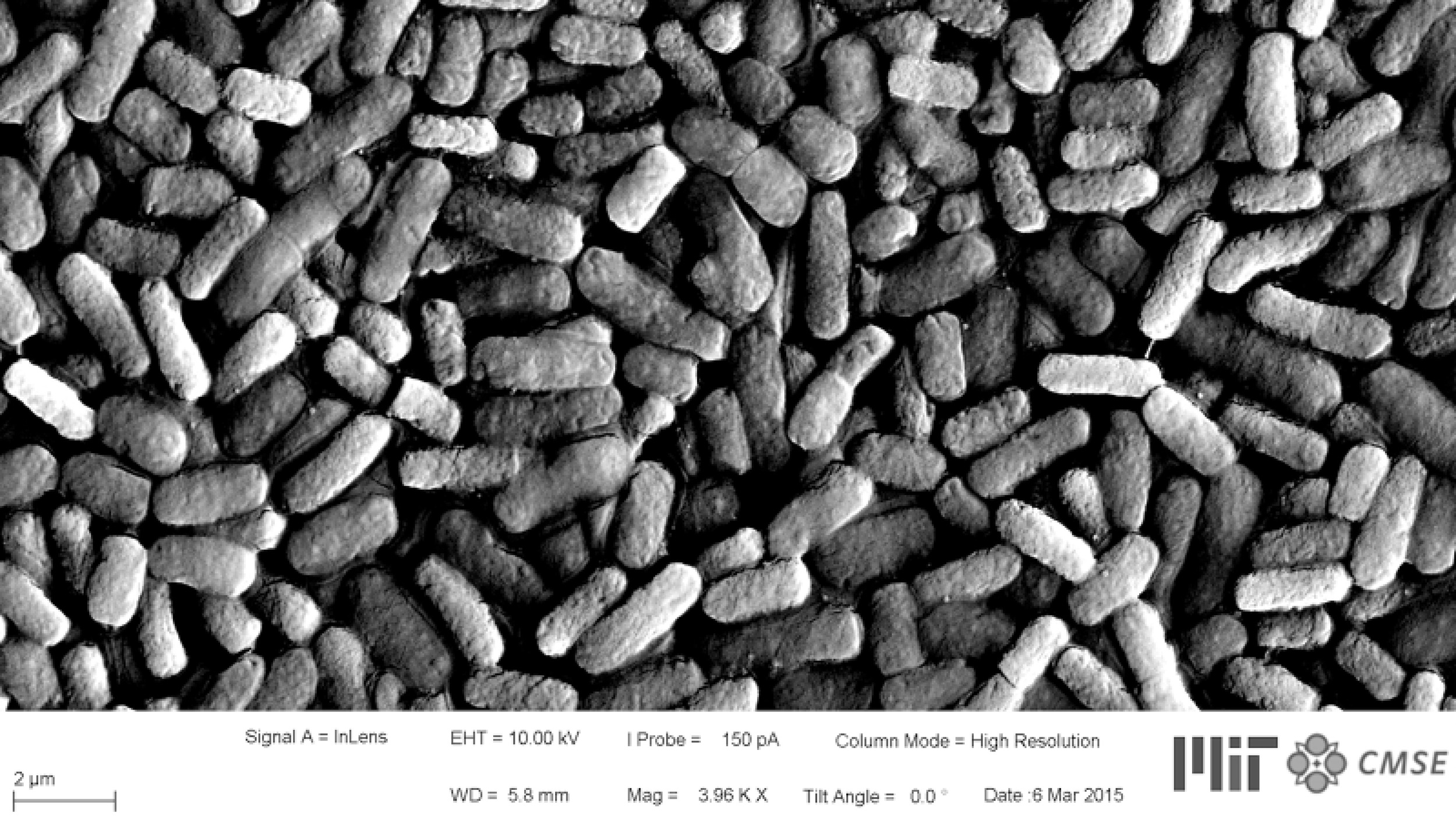

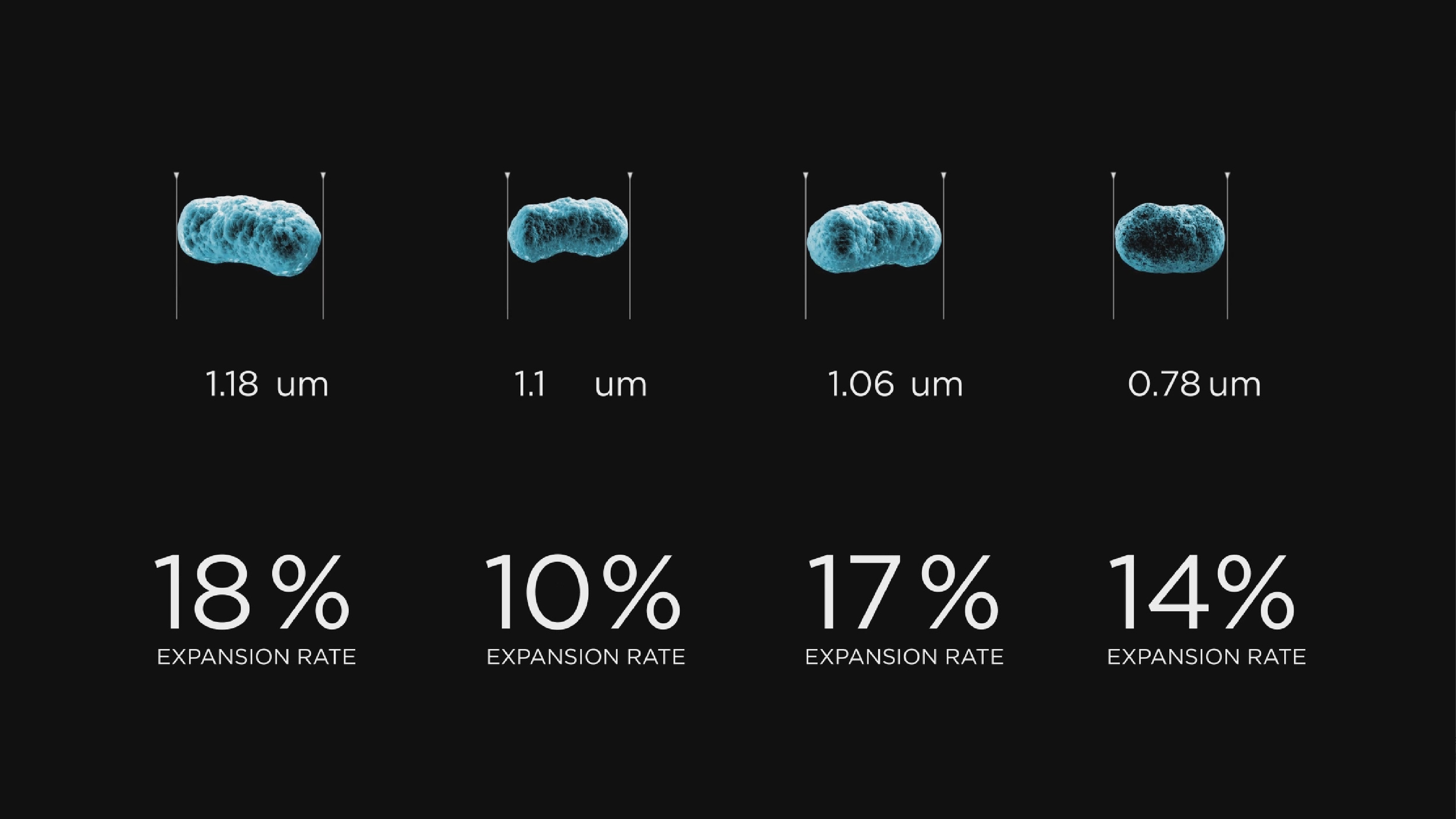

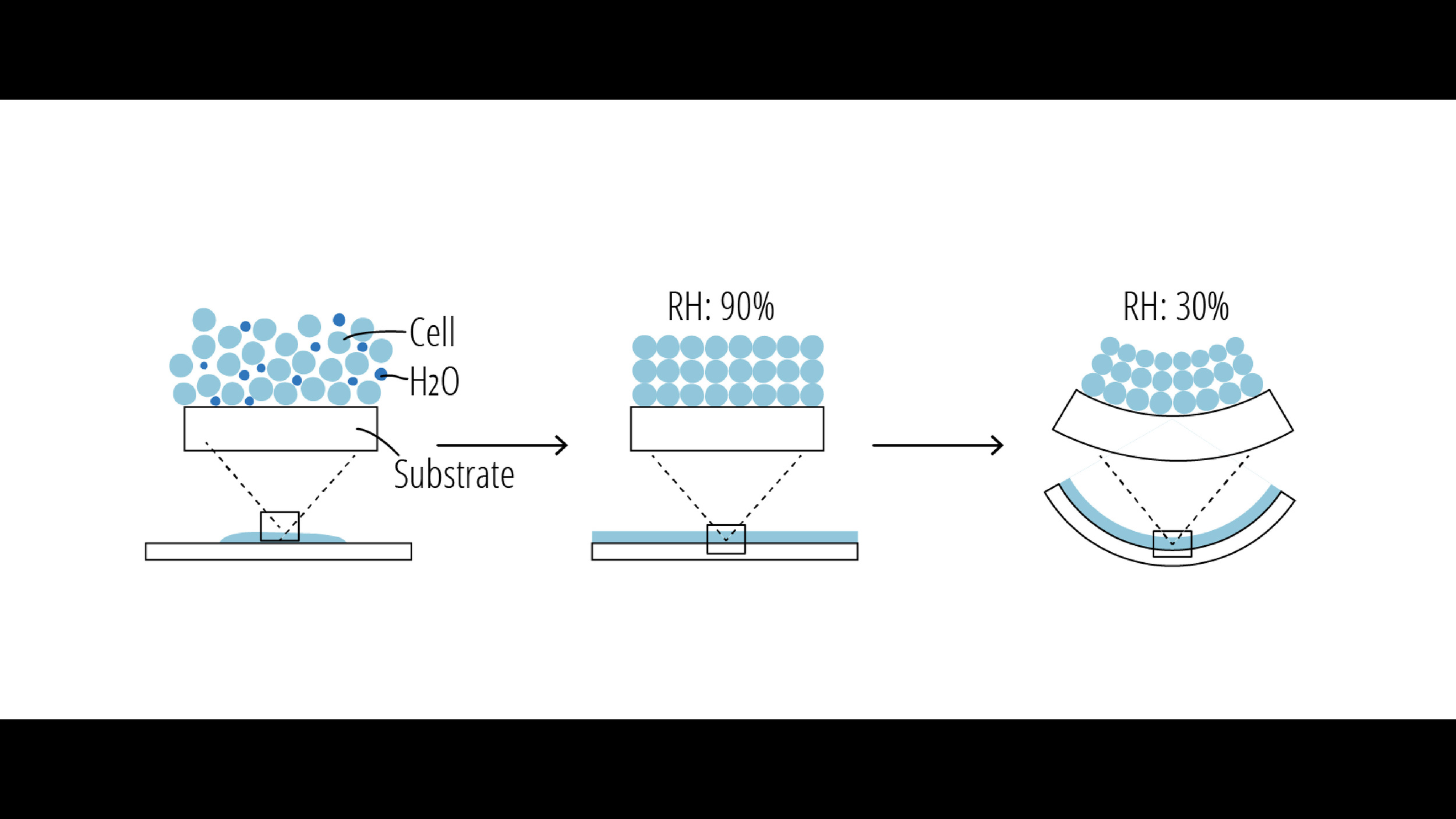

Concept

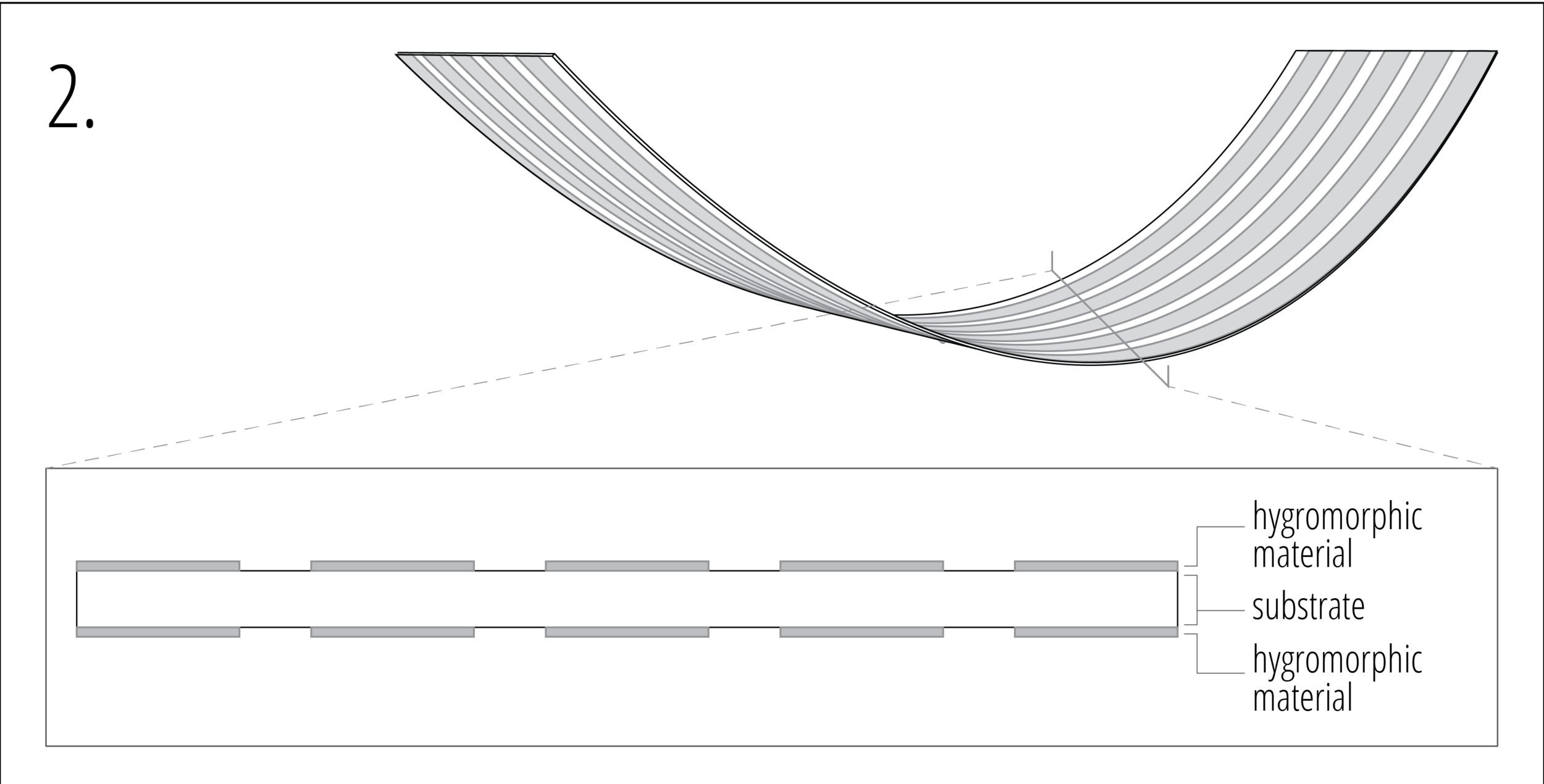

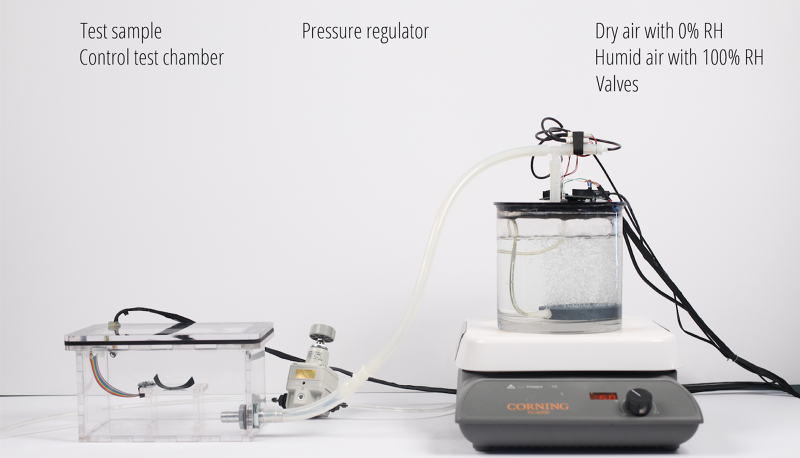

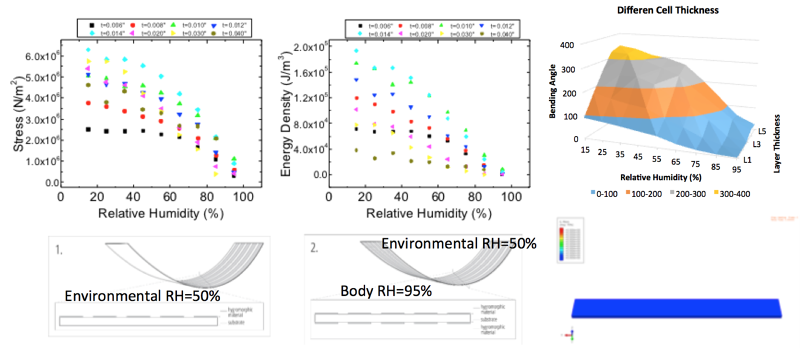

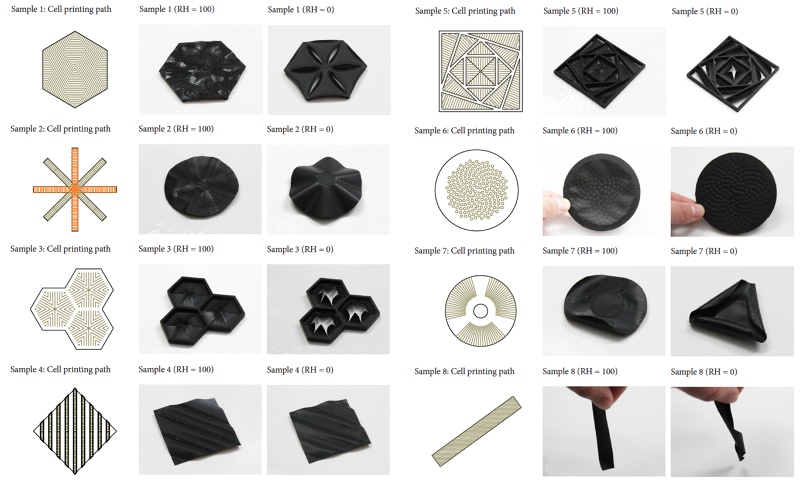

Nature has engineered its own actuators, as well as the efficient material composition, geometry and structure to utilize its actuators and achieve functional transformation. Based on the natural phenomenon of cells’ hygromorphic transformation, we introduce the living Bacillus Subtilis natto cell as a humidity sensitive nano-actuator. In this research, we unfold the process of exploring and comparing cell types that are proper for design use, the development of the composite biofilm, the development of the responsive structures, the control setup for actuating biofilms, and a design-simulation-fabrication platform.

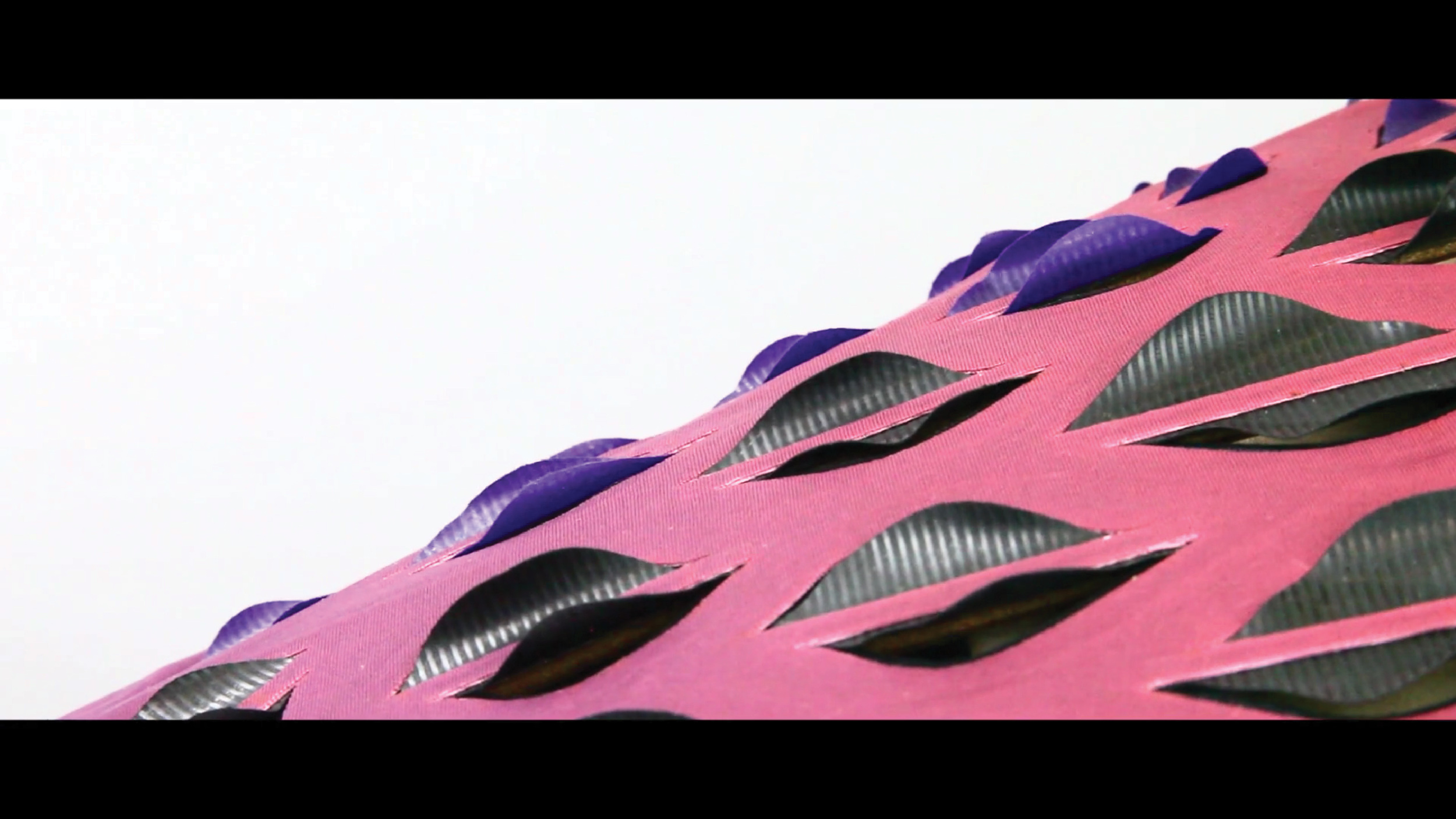

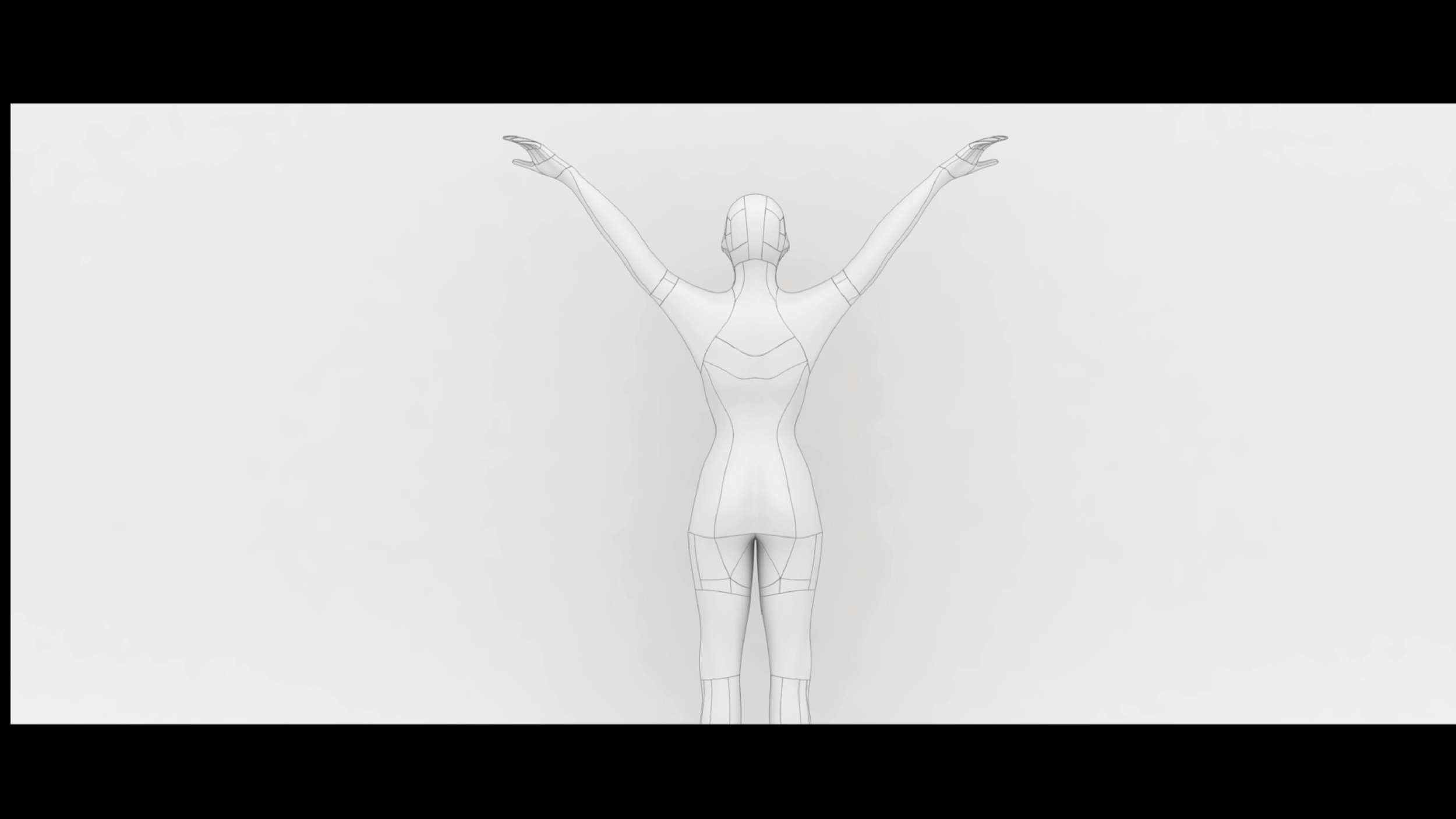

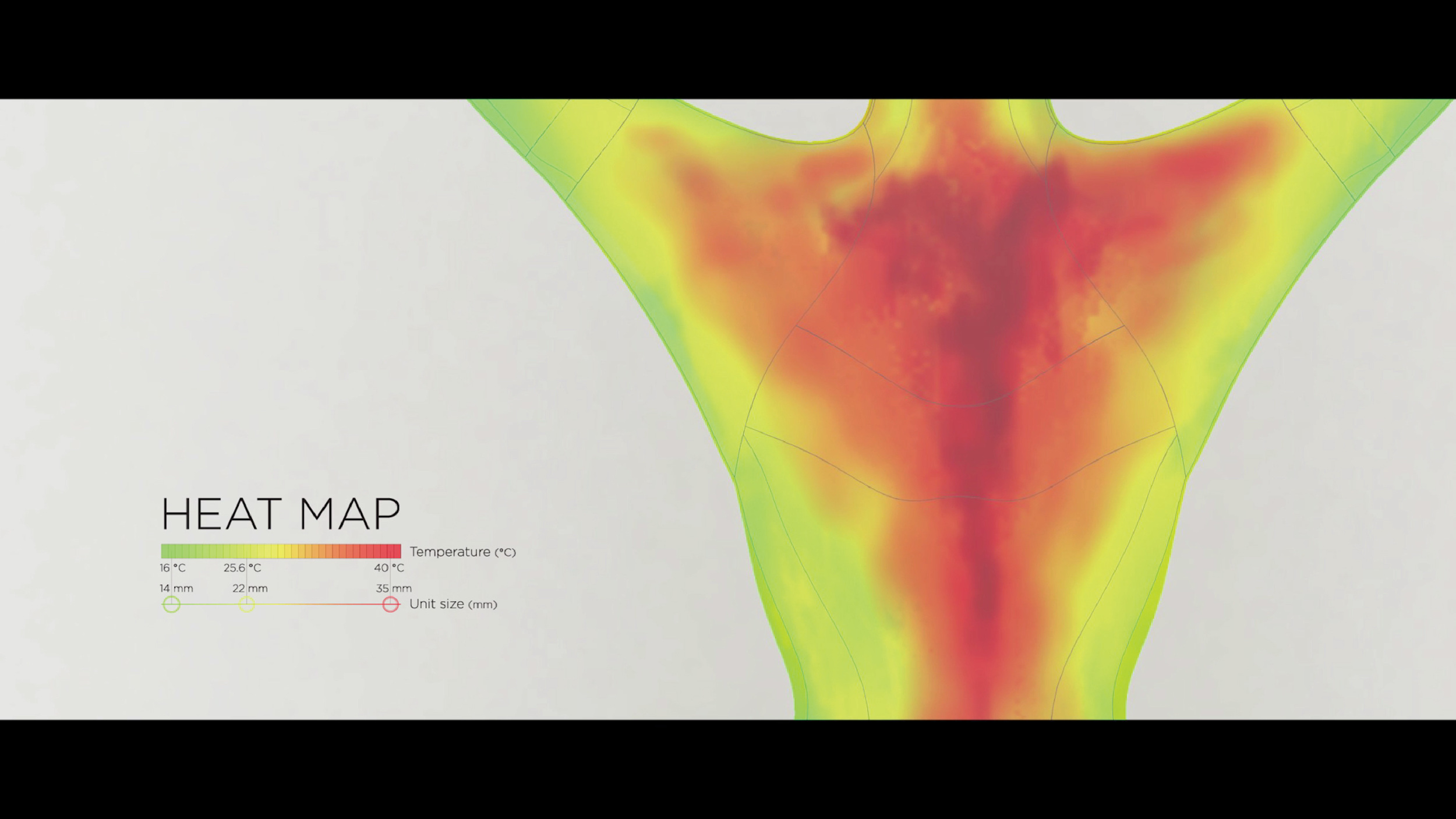

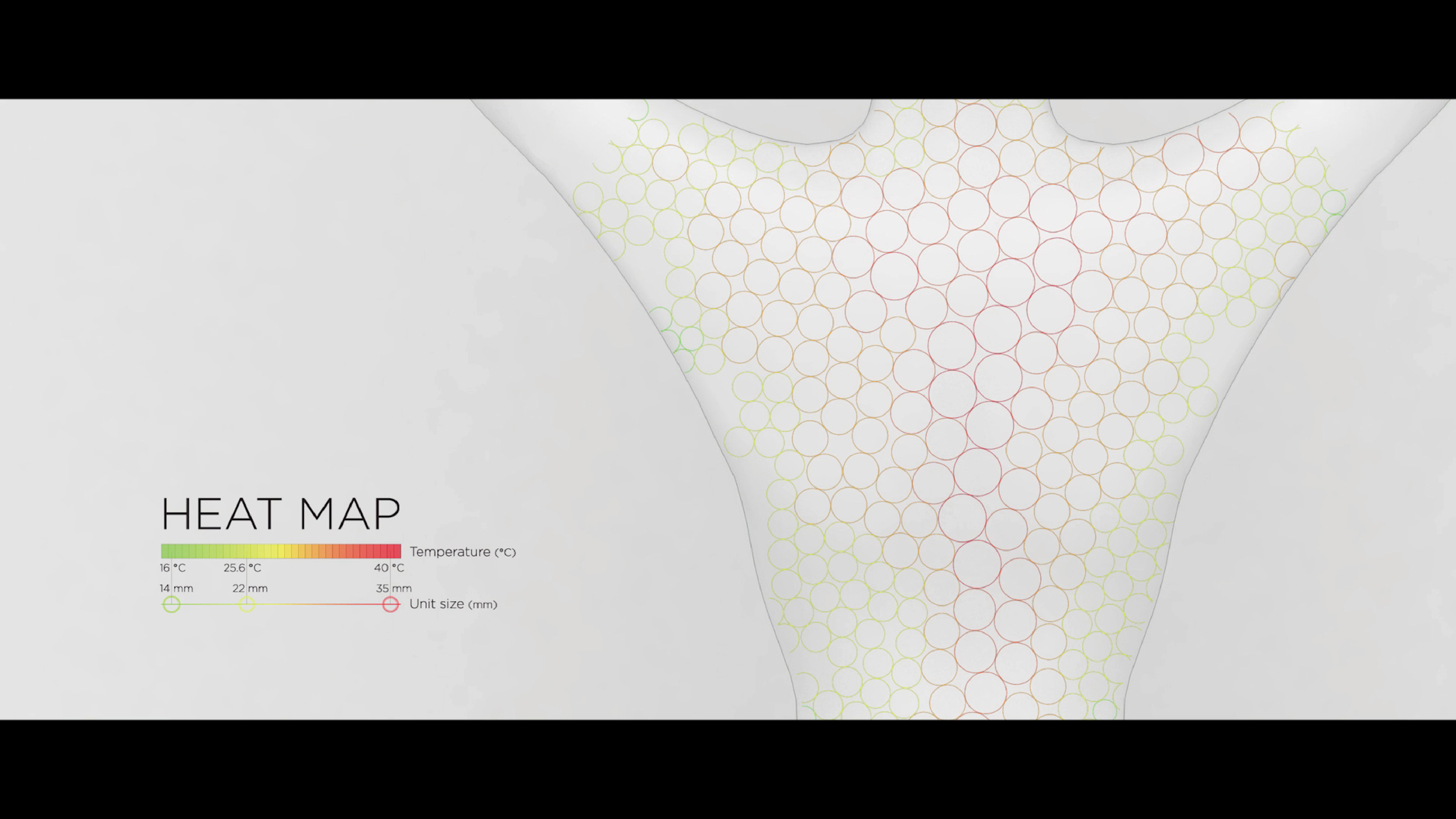

The Second Skin

These animate cells are harvested in a bio lab, assembled by a micron-resolution bio-printing system, and transformed into a responsive fashion, a “Second Skin”. We can now observe the self-transforming biological skin activated by living bacteria. The synthetic bio-skin reacts to body heat and sweat, causing flaps around heat zones to open, enabling sweat to evaporate and cool down the body through an organic material flux. In collaboration with New Balance, bioLogic is bringing what once may have lived in the realm of fantasies into the world of sportswear.

![chinyi [已復原]-32.jpg](https://images.squarespace-cdn.com/content/v1/56b7dcc759827e543656636e/1455719638349-4ESGA8B7ID47U94CD4VE/chinyi+%5B%E5%B7%B2%E5%BE%A9%E5%8E%9F%5D-32.jpg)

![chinyi [已復原]-27.jpg](https://images.squarespace-cdn.com/content/v1/56b7dcc759827e543656636e/1455719634196-HCS5CHR9HYI3WDC524F5/chinyi+%5B%E5%B7%B2%E5%BE%A9%E5%8E%9F%5D-27.jpg)

![chinyi [已復原]-26.jpg](https://images.squarespace-cdn.com/content/v1/56b7dcc759827e543656636e/1455719634170-38VE67LBH3JN8N3LCR89/chinyi+%5B%E5%B7%B2%E5%BE%A9%E5%8E%9F%5D-26.jpg)

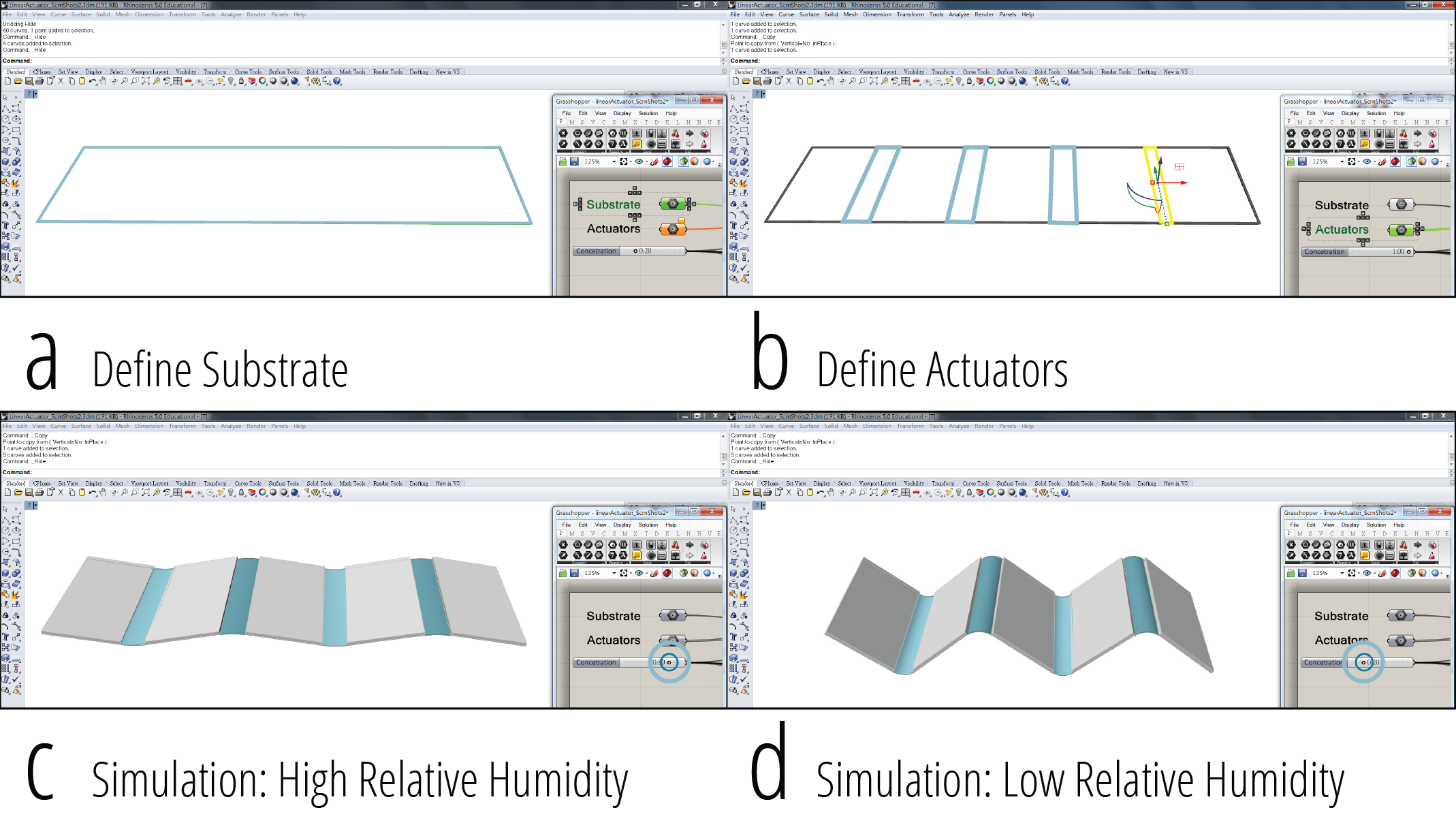

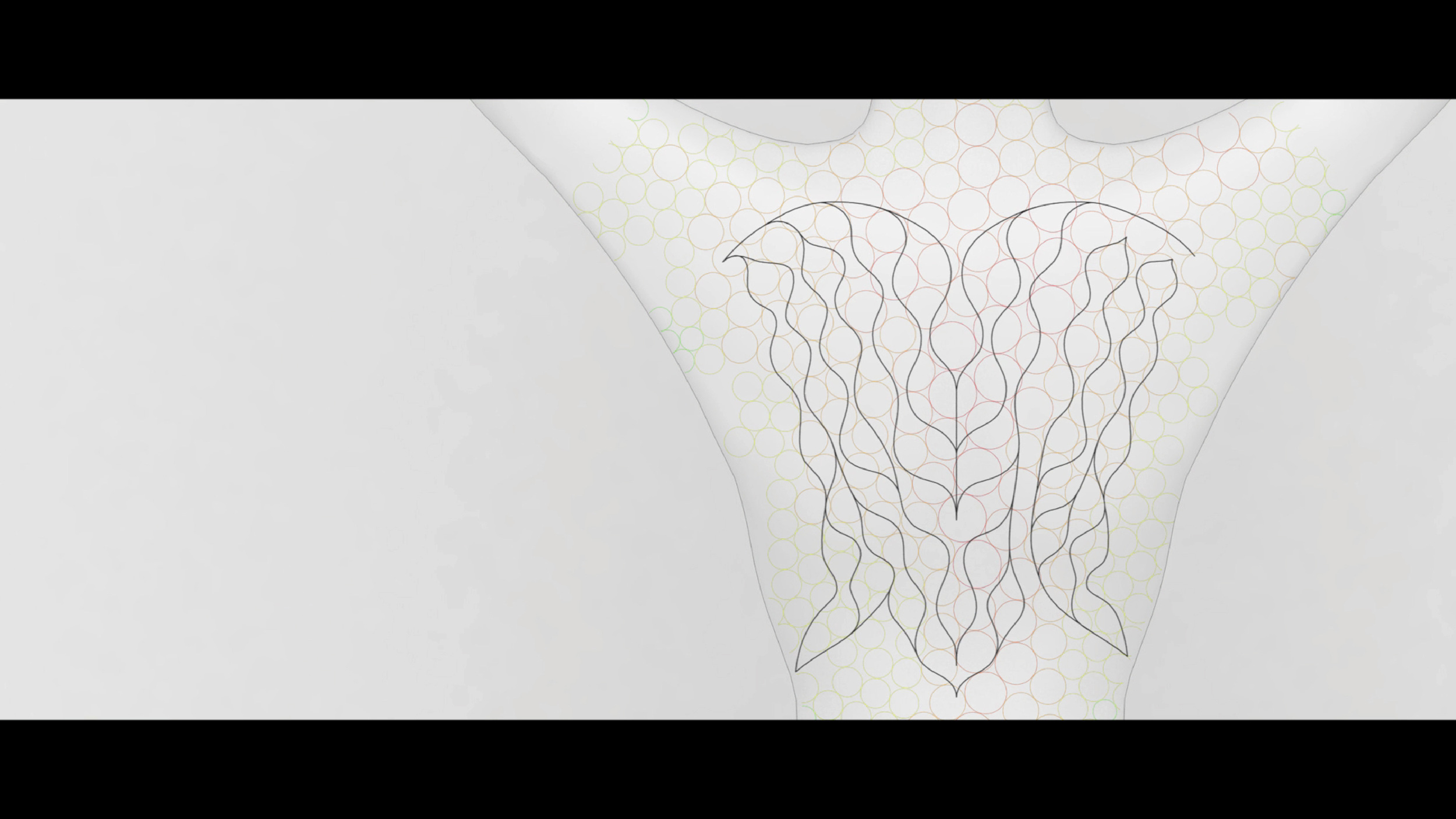

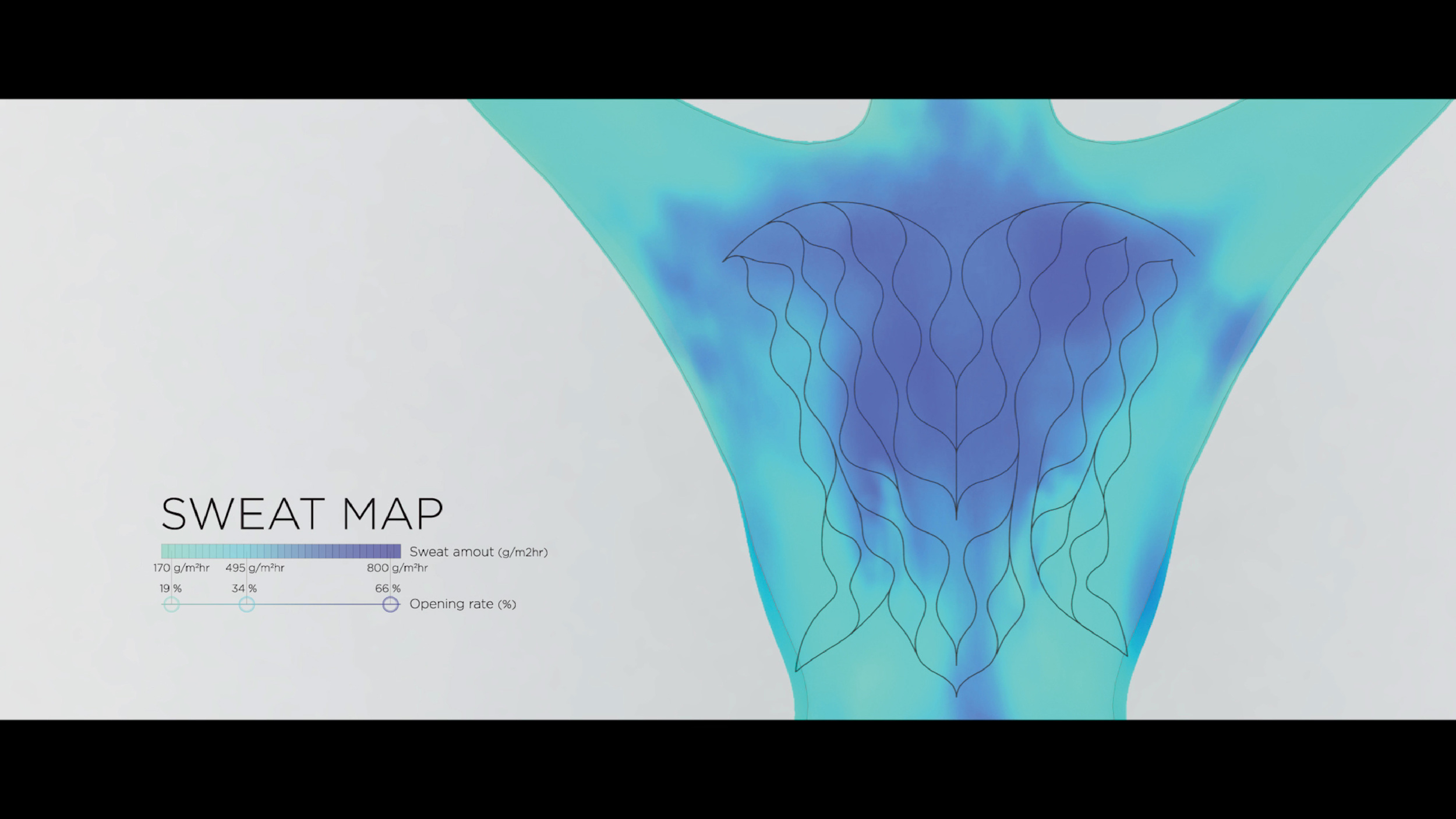

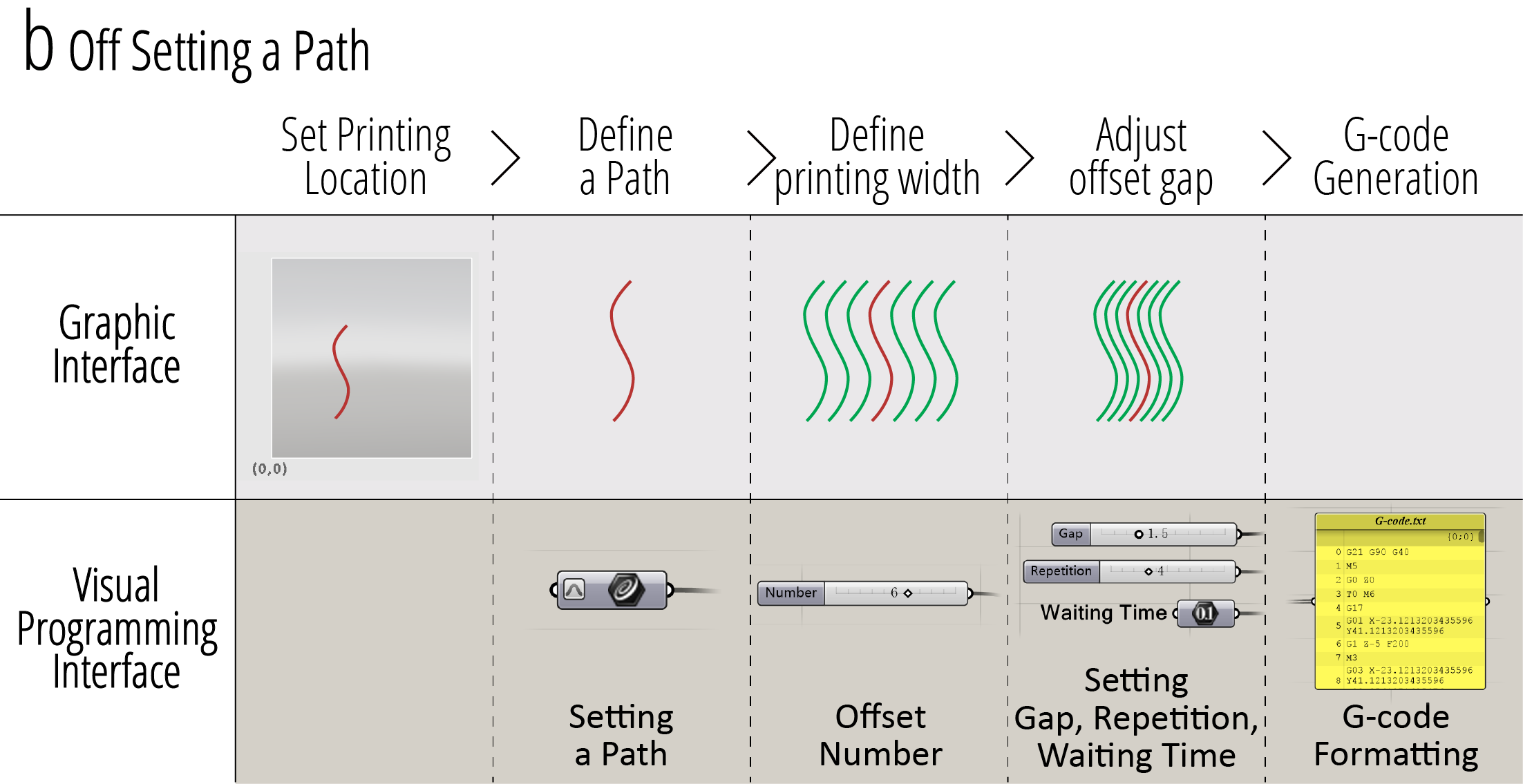

Interactive Design/Simulation Process

To be able to design the garment and other applications, we create a interactive feedback loop among human body, bio-film, and the environment. During the research process, we are always trying to modify the material properties based on our experimental data, and we have to uses these properties to explore all the design possibilities of our bio-film. Therefore, we built the design interface which can not only simulate the material behavior, but more importantly, give the designers a real-time feedback, creating a seamless connection from experiment to design to fabrication.

![chinyi [已復原]-22.jpg](https://images.squarespace-cdn.com/content/v1/56b7dcc759827e543656636e/1455718772817-BJD29P7RLAXTK12PIDDJ/chinyi+%5B%E5%B7%B2%E5%BE%A9%E5%8E%9F%5D-22.jpg)

![chinyi [已復原]-23.jpg](https://images.squarespace-cdn.com/content/v1/56b7dcc759827e543656636e/1455718775416-SB8I4GUYCJW9O7C9PXZF/chinyi+%5B%E5%B7%B2%E5%BE%A9%E5%8E%9F%5D-23.jpg)

![chinyi [已復原]-48.jpg](https://images.squarespace-cdn.com/content/v1/56b7dcc759827e543656636e/1455719082592-N2QTTNUAHPH9US9C612L/chinyi+%5B%E5%B7%B2%E5%BE%A9%E5%8E%9F%5D-48.jpg)

![chinyi [已復原]-25.jpg](https://images.squarespace-cdn.com/content/v1/56b7dcc759827e543656636e/1455719015312-7MZXVYKG61ZSXKB8A0I6/chinyi+%5B%E5%B7%B2%E5%BE%A9%E5%8E%9F%5D-25.jpg)

![chinyi [已復原]-24.jpg](https://images.squarespace-cdn.com/content/v1/56b7dcc759827e543656636e/1455719005097-PLY04WO29C0P0JB86BOG/chinyi+%5B%E5%B7%B2%E5%BE%A9%E5%8E%9F%5D-24.jpg)

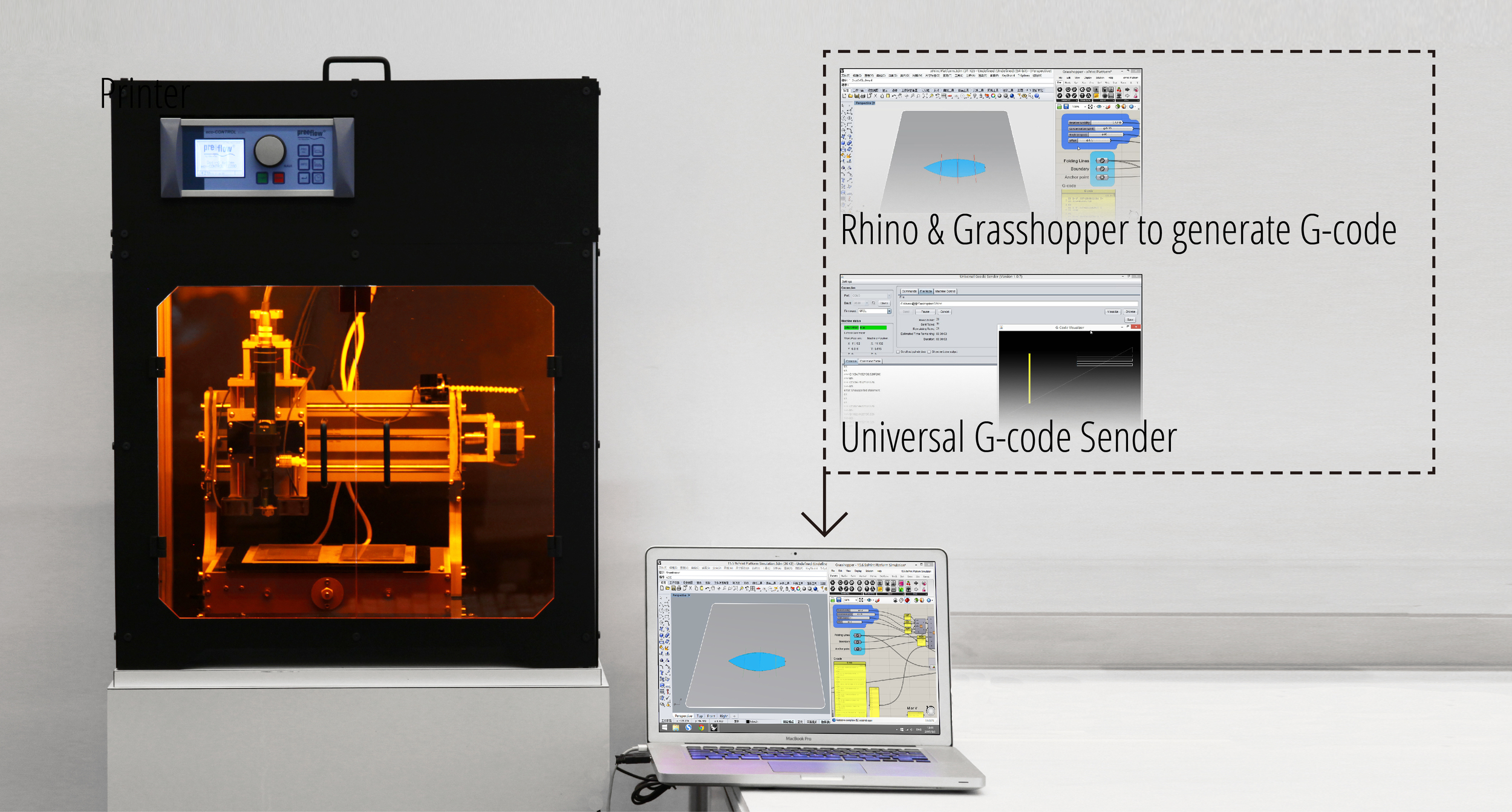

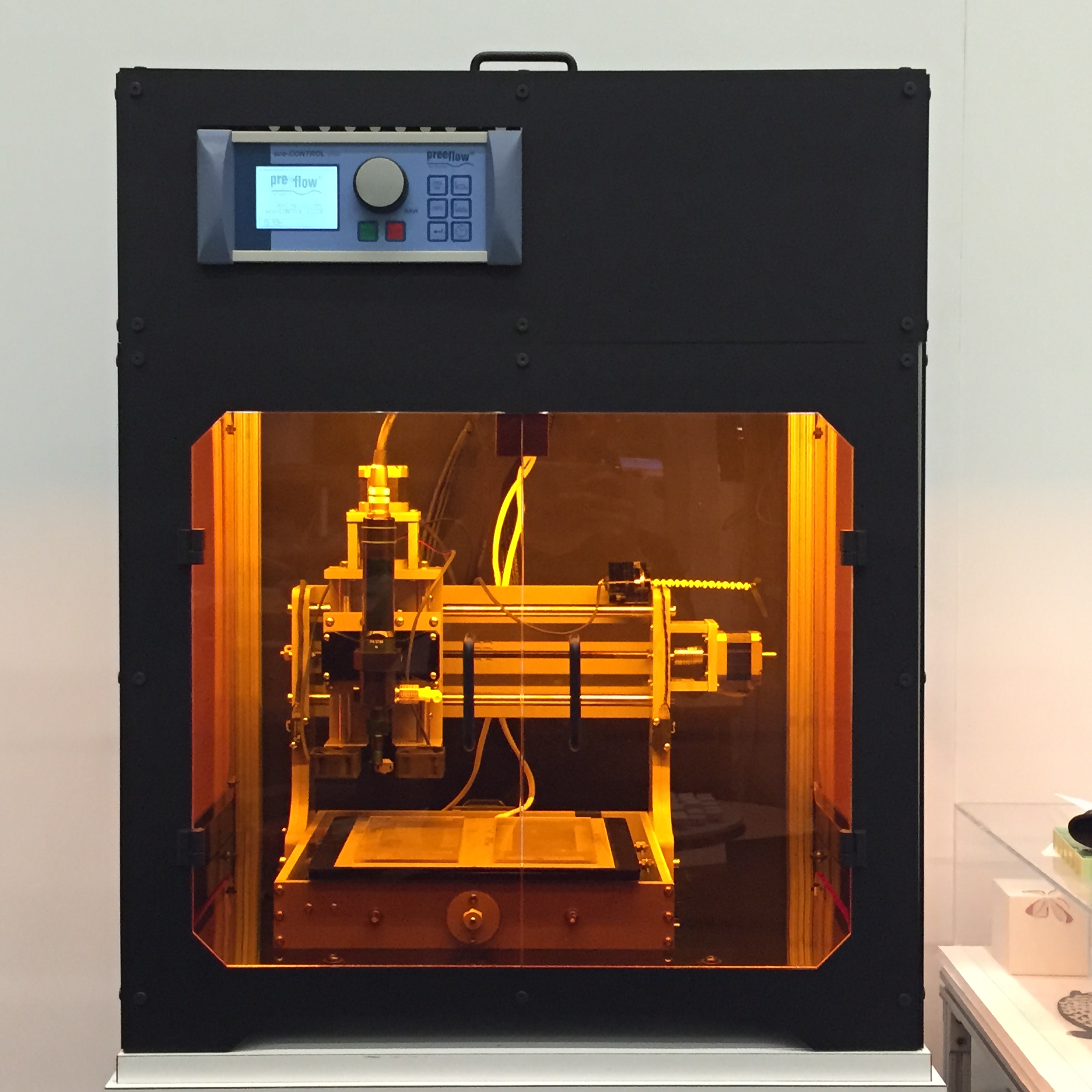

Engineering, Fabrication and the xPrinter

We have developed a various of ways to make transformable units using our bio-film, and we also explored three different types of fabrication process: manual pipetting, atomizing and inkjet printing. For inkject printing, to deposit the cell precisely onto the substrate, we built our multi-functional modular printer, replacing the drill of a commercial CNC gantry to a nuzzle, customizing control system, and designing functional units.

![chinyi [已復原]-46.jpg](https://images.squarespace-cdn.com/content/v1/56b7dcc759827e543656636e/1455720603612-SS5NP1CSRU60I8E3JCDV/chinyi+%5B%E5%B7%B2%E5%BE%A9%E5%8E%9F%5D-46.jpg)

![chinyi [已復原]-13.jpg](https://images.squarespace-cdn.com/content/v1/56b7dcc759827e543656636e/1455720853018-4OWZN22C0SL575MB63OT/chinyi+%5B%E5%B7%B2%E5%BE%A9%E5%8E%9F%5D-13.jpg)

![chinyi [已復原]-49.jpg](https://images.squarespace-cdn.com/content/v1/56b7dcc759827e543656636e/1455720519294-PLX6QEWEO0PDNBJ2GRRH/chinyi+%5B%E5%B7%B2%E5%BE%A9%E5%8E%9F%5D-49.jpg)

Scientific Study

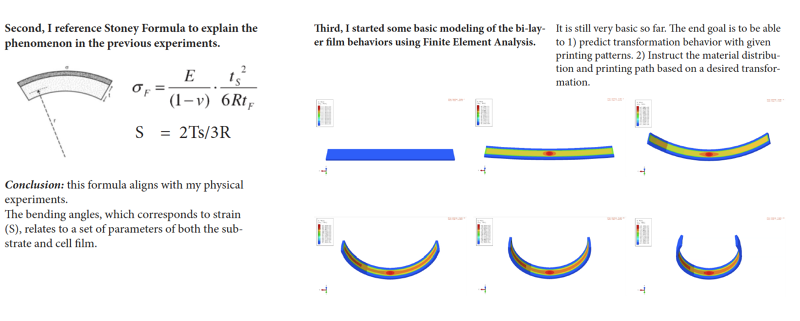

In collaboration with Postdoc Wang Wang from MIT Chemical Engineering department, and professor Xuanhe Zhao from MIT Mechanical Engineering department, I am co-first-authoring a paper targeting on a scientific journal, with the focus of studying the underlining mechanism of the multi-functional living nano-actuators. A glimpse of the contents from the study:

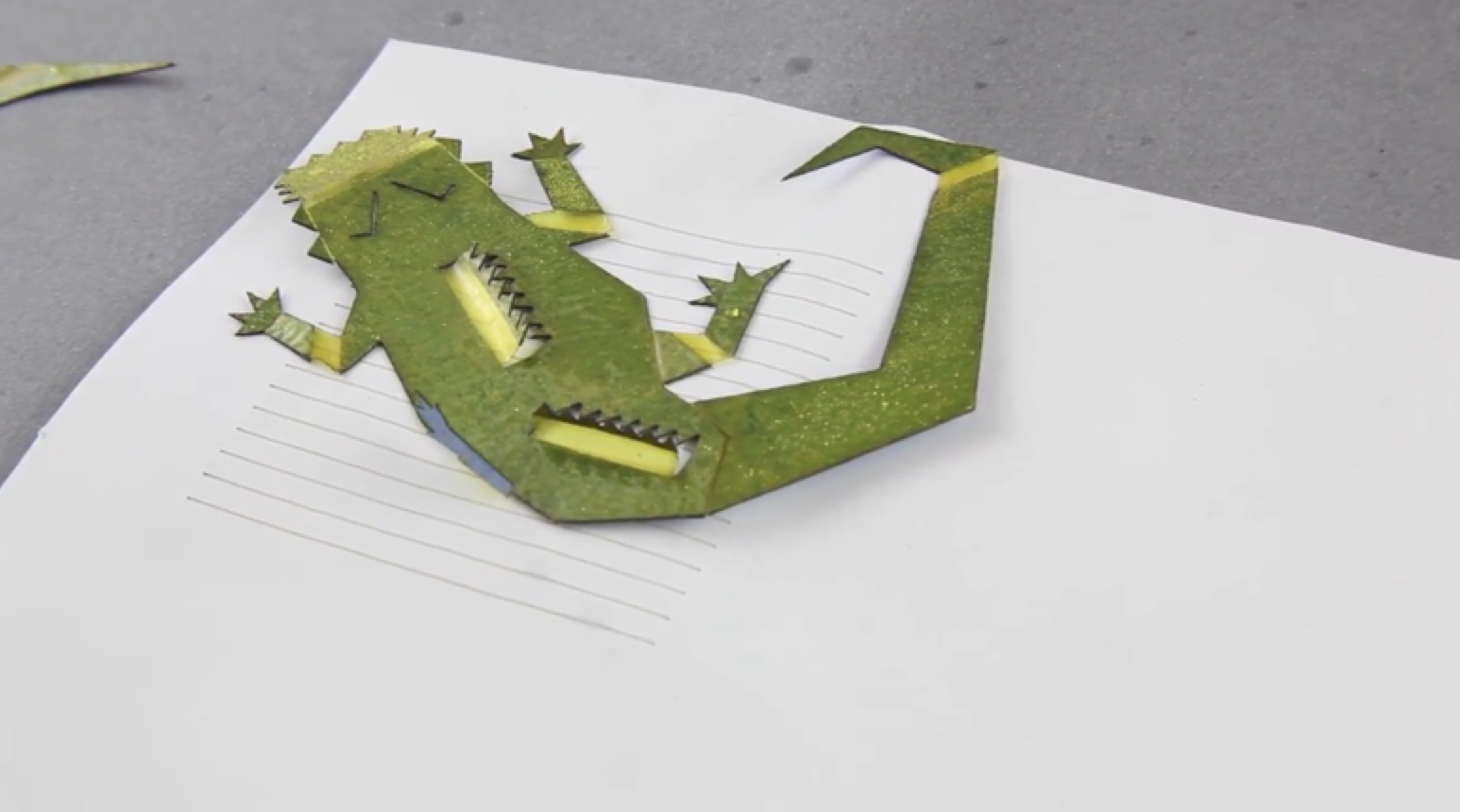

Interactive Design Applications

Beyond garment design, we have developed various interaction ideas, including shape changing lampshades, color and shape changing flowers, living tea leaves and animated paper toys.

![chinyi [已復原]-51.jpg](https://images.squarespace-cdn.com/content/v1/56b7dcc759827e543656636e/1455721369012-7UJTWBEFC26XSZ1UYMG9/chinyi+%5B%E5%B7%B2%E5%BE%A9%E5%8E%9F%5D-51.jpg)

Exhibition

We curated and designed an artistic exhibition to help celebrate MIT Media Lab 30's anniversary. In the exhibition, we created sculpture with transformable films, steambot with transformable primitives, as well as 2.5D biofilms. We were intended to create the conversation between "the born" and "the made" world.